|

| Description |

Performance |

Specification |

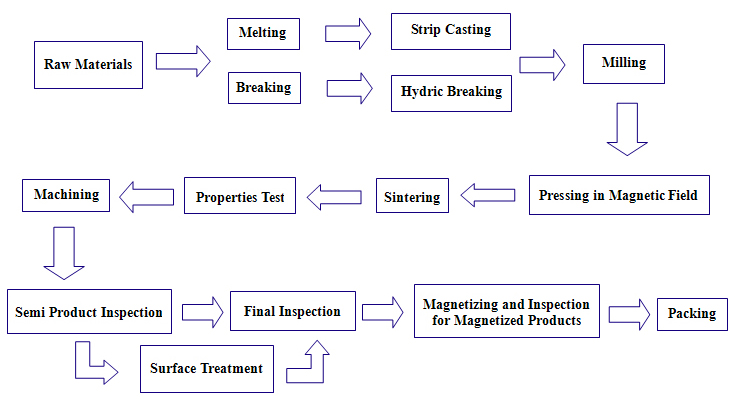

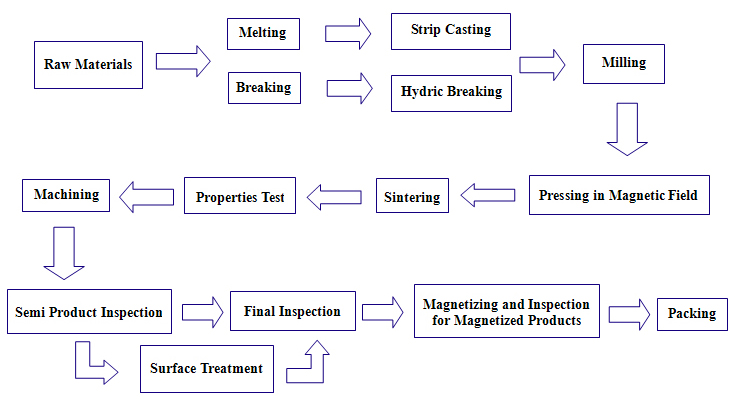

Production Process |

|

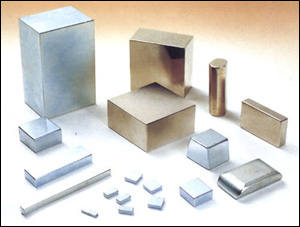

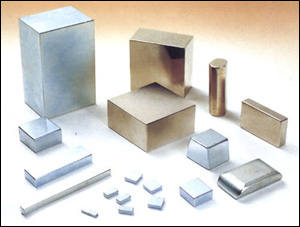

Sintered NdFeB:

- High and Multi-grade Magnetic properties.

- Surface treatment is needed for the corrosion resistant purpose, you could select needed coating from below.

- Electroplating coating with Ni, Cu, Sn, Zn, Au, Ag or combinations thereof.

- Epoxy resin, sprayed or electrodeposition coated.

- Parylene coating.

- PTFE-coated.

|

|

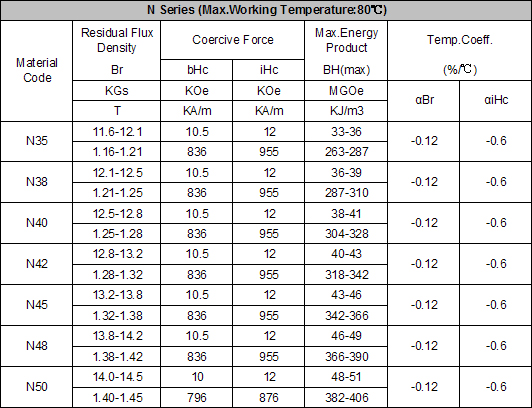

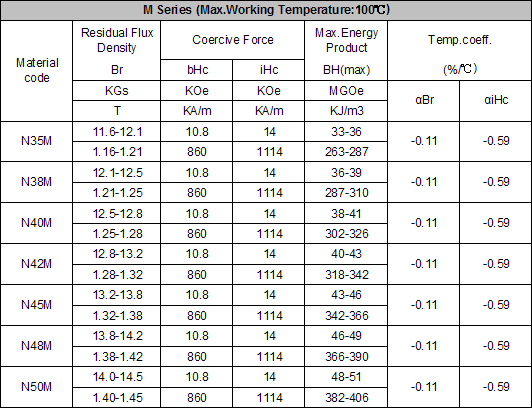

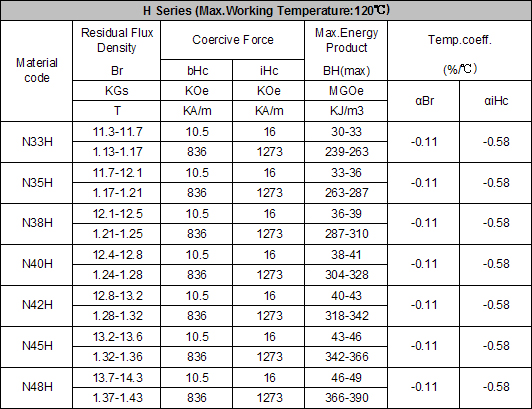

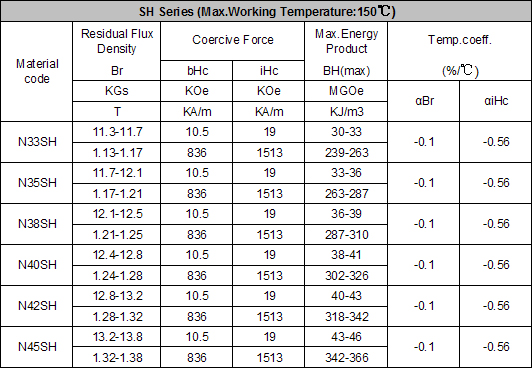

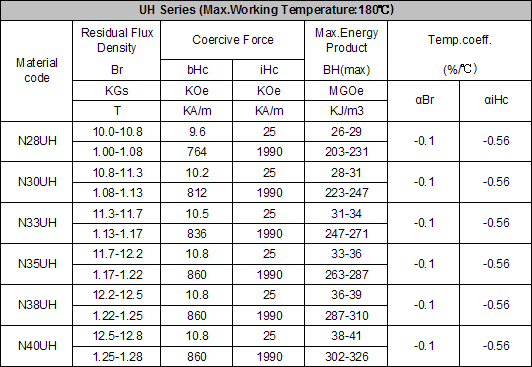

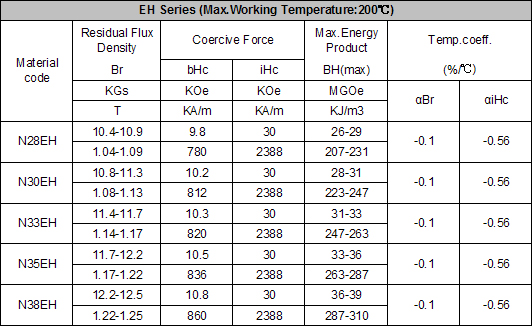

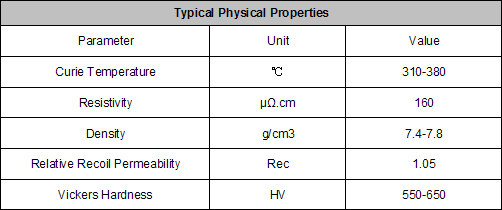

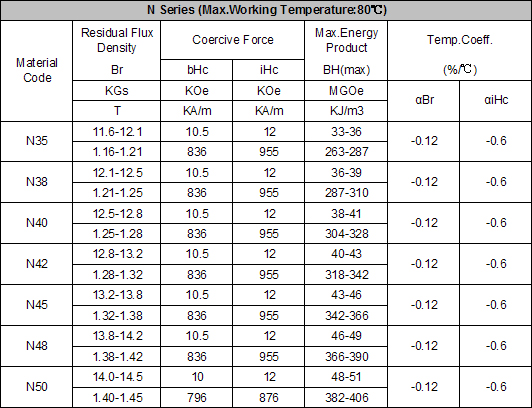

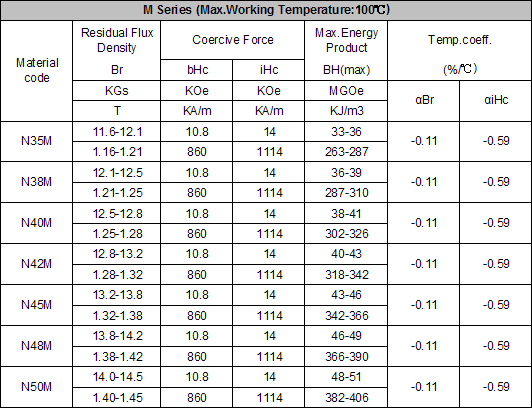

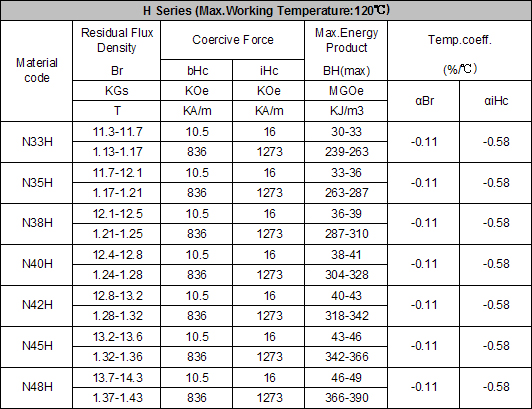

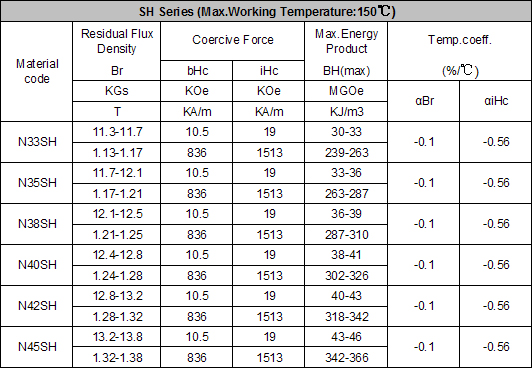

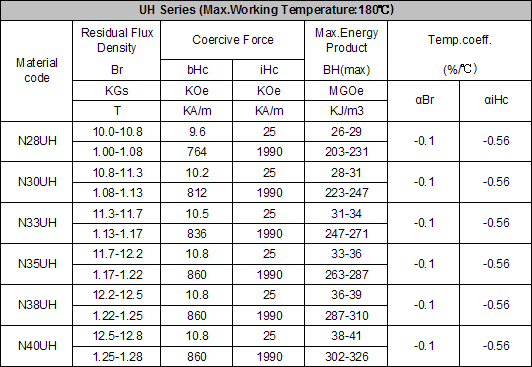

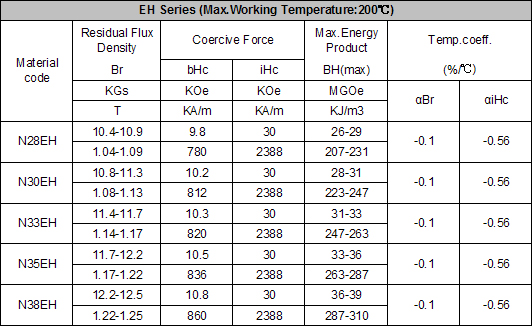

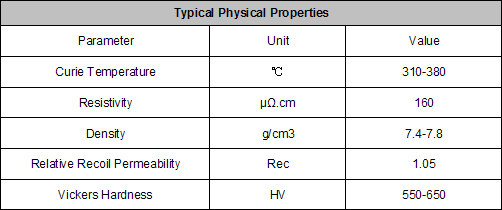

Magnetic Properties

Note:

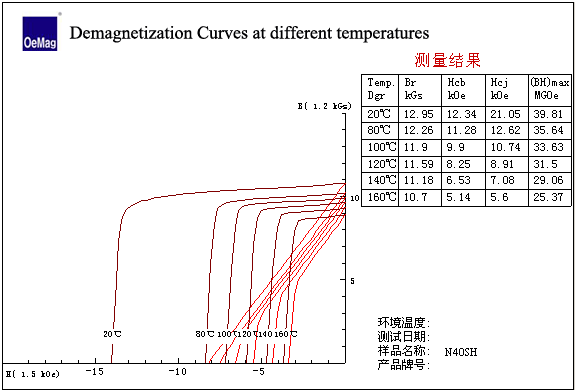

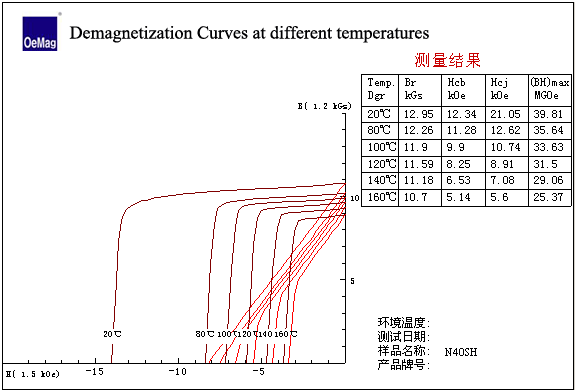

1. The above mentioned data of magnetic parameters and physical properties are given at the room temperature.

2. The maximum working temperature of magnets is changeable due to the ratio between the length and diameter as well as the environmental factors.

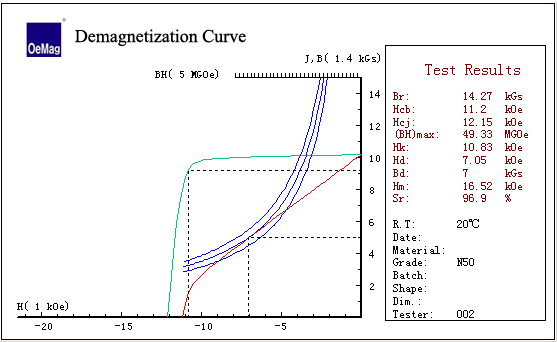

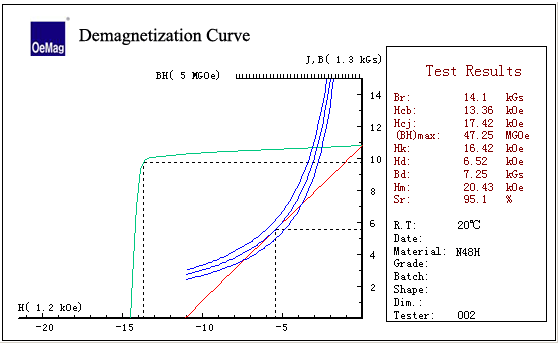

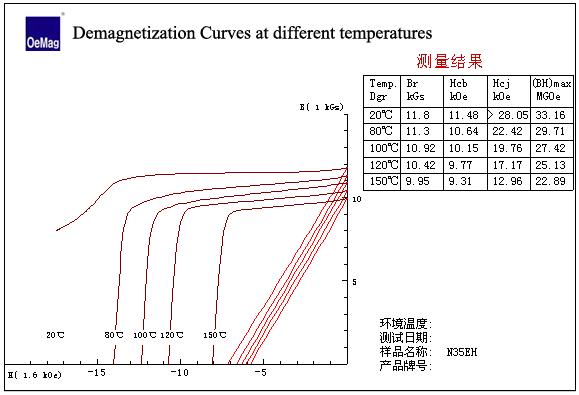

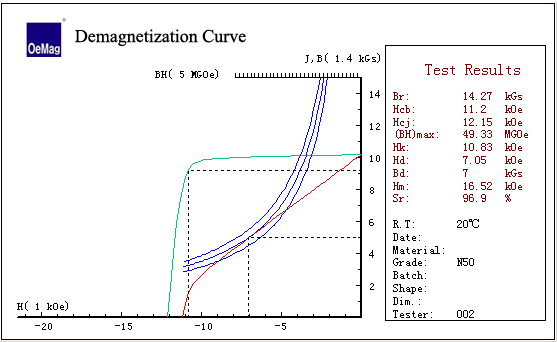

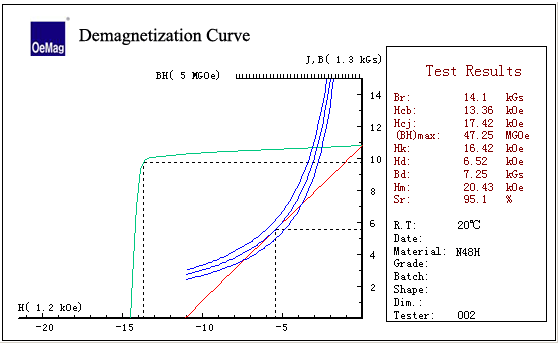

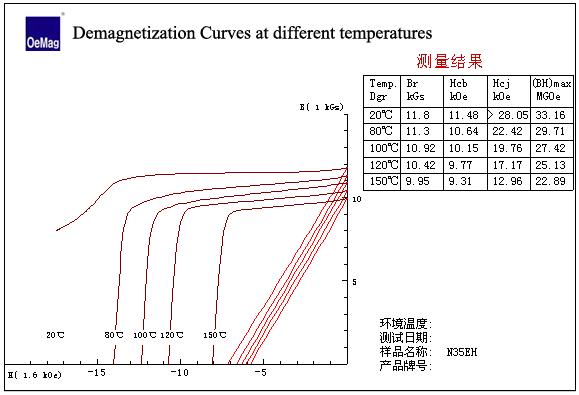

Demagnetization Curves

|

General Dimension and Standard Tolerance

|

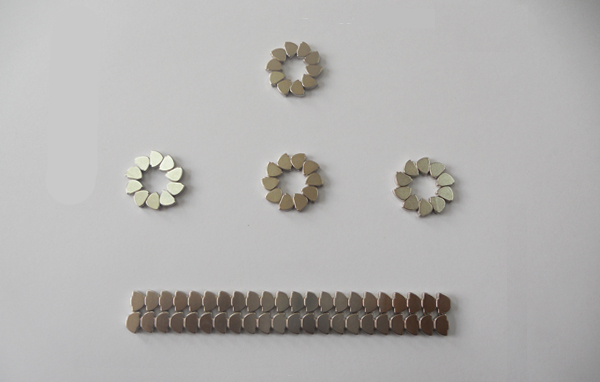

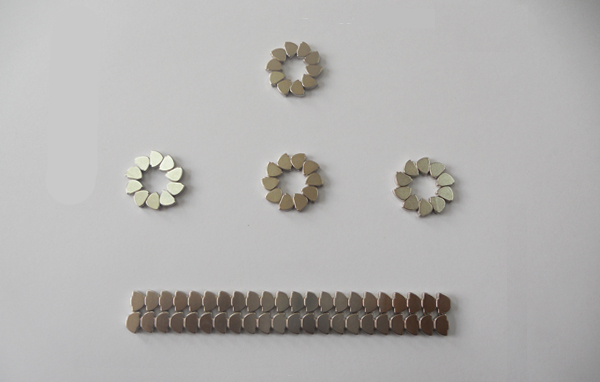

Disc |

D(mm) |

H(mm) |

|

Max |

150 |

50 |

|

Min |

3 |

0.7 |

|

Tolerance |

+/-0.1 |

+/-0.1 |

|

Ring |

OD(mm) |

ID(mm) |

H(mm) |

|

Max |

170 |

120 |

50 |

|

Min |

3 |

1.5 |

0.5 |

|

Tolerance |

+/-0.1 |

+/-0.1 |

+/-0.1 |

|

Block |

L(mm) |

W(mm) |

H(mm) |

|

Max |

150 |

150 |

50 |

|

Min |

2 |

1.5 |

0.5 |

|

Tolerance |

+/-0.1 |

+/-0.1 |

+/-0.1 |

Note:

Above are the general dimensions we make for the NdFeB magnets, for the specific magnets you required, please contact us with the detailed informaiton.

|

Available Coatings of Sintered NdFeB Magnets |

|

Surface |

Coating |

Thickness of coating |

Color |

Salt Spray Test Standard (hours)

5%NaCl,35℃ |

|

Nickel |

Ni |

10-20μm |

Bright Silver |

﹥4 |

|

Ni+Ni |

15-20μm |

Bright Silver |

24-48 |

|

Ni+Cu+Ni |

15-30μm |

Bright Silver |

﹥48 |

|

Black Nickel |

Ni+Cu+Ni |

10-20μm |

Bright Black |

48-72 |

|

Zinc |

Zn |

10-15μm |

Light Blue |

16-48 |

|

Color Zn |

10-15μm |

Multicolor |

24-72 |

|

Tin |

Ni+Cu+Ni+Sn |

10-25μm |

Silver |

48-72 |

|

Gold |

Ni+Cu+Ni+Au |

6-10μm |

Gold |

----- |

|

Ag |

Ni+Cu+Ni+Ag |

6-10μm |

Silver |

----- |

|

Epoxy |

Epoxy |

10-25μm |

Black/Grey |

24-48 |

|

Ni+Cu+Epoxy |

10-25μm |

Black/Grey |

48-72 |

|

Zn+Epoxy |

10-25μm |

Black/Grey |

48-72 |

|

Temporary Protection |

Passivation |

1-2μm |

Silver grey |

----- |

|

Phosphated |

1-2μm |

Silver grey |

----- |

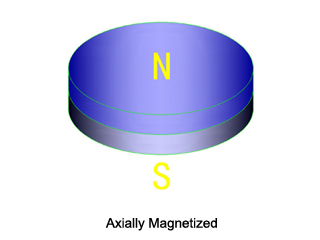

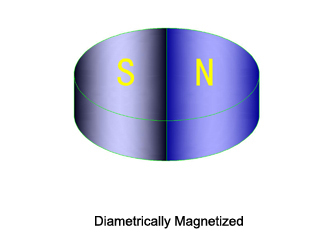

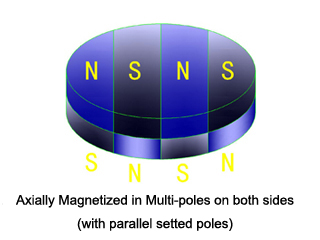

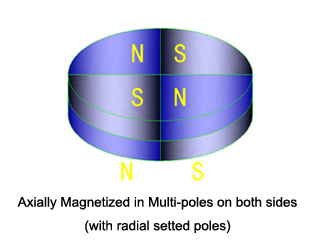

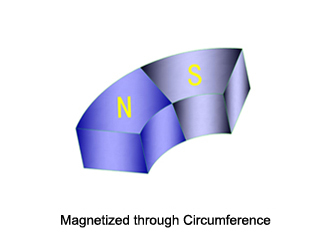

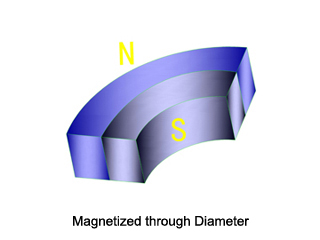

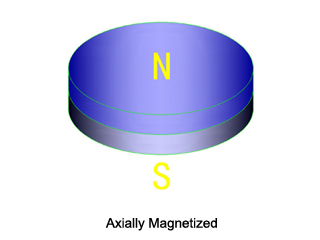

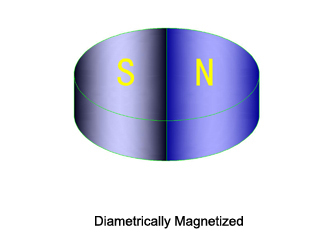

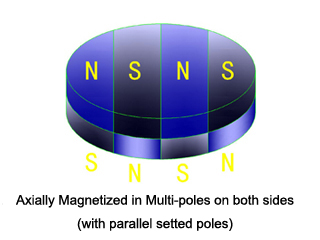

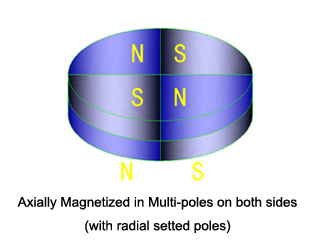

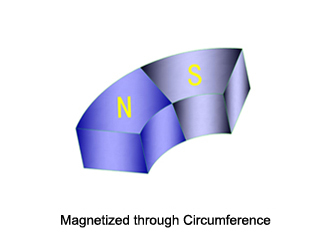

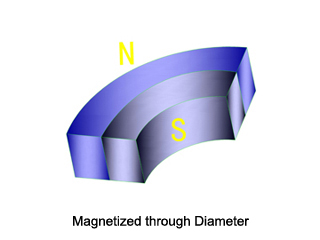

Magnetization

|

|

|

|

|

|

|